LEIFERT INDUCTION is developing and producing innovative inductive heating systems for mounting and dismounting of shrink fits connections as well as for preheating of workpieces.

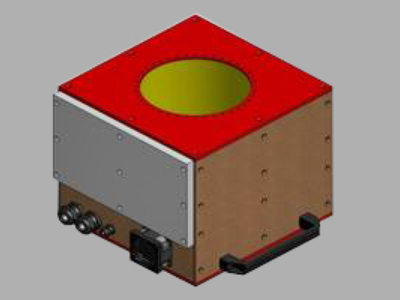

LEIFERT INDUCTION is developing air cooled middle frequency generators for induction heating of

ferromagnetical work pieces. These innovative middle frequency generators with IGBT –transistor technology

can be used in different ways. It is possible to work with programmable temperature profiles, only in the

mode of temperature controlling or only with a simple time controlling.

All kinds of models will be manufactured close to the customer. To optimize the process on site it is

possible to equip the generators with different parameters. The wide range of power supply guaranteed an

operation all over the world.

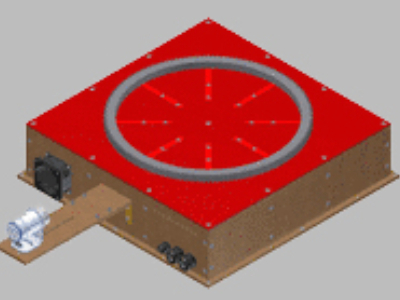

An induction table contains a plane coil. These kinds of induction coils is capable for heating up of gear rings, small bearings and rings. Due to the heat treatment from the bottom to the top it is necessary to consider the height of the work piece.

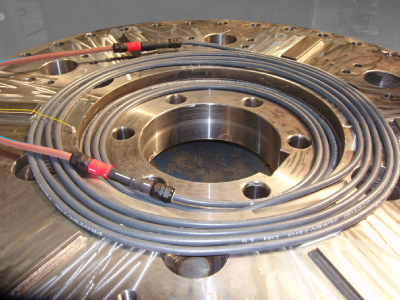

In cases of hard to reach heating positions and no consideration of set-up time the flexible induction coil is predestinated. It is an excellent tool for prototype experiments and it is very suitable for heating up weld seams.

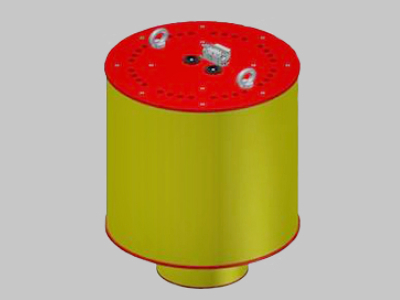

The work piece needs to be taken into the induction coil so that the induction coil covers the work piece. An induction coil which takes advantage of the inner field has always a better efficiency factor towards an outer field induction coil.

An outer field induction coil is predestinated to heat up bores. The induction coil will be placed inside the bore.

PRODUCTS