Towards gas heating the inductive preheating has several benefits for weld seams.The influence of the heat energy acts direct to the work piece and is reproducible and controllable. LEIFERT INDUCTION provides special designed generators and induction coils which prove itself in practice.

During welding of steel the structure inside the heat affected zone (beside the seam) becomes a hardness intensity which is negative for the quality. The process of hardness increases more quickly depending on the temperature difference between the seam and the area beside the seam. Therefore the welding parts need to be heated up to minimize the hardness intensity. The temperature to avoid cold cracks depends on the thickness of the work pieces, the heat dissipation, the alloy of the material and the heat treatment during the welding process.

Due to quality requirements it is necessary to preheat the welding seams in pipeline and offshore constructions. The inductive preheating equipment meets a special challenge in building a welding seam for substructures like Tripods and Monopiles for offshore wind energy plants. The solid construction of the generators from LEIFERT Induction ensures a sophisticated tool for all requirements in pre-heating processes.

Especially for preheating of welding seams LEIFERT INDUCTION has developed a flexible, air cooled induction coil. Excellent mechanical features coupled with fireproofed materials build a special tool in the area of welding.

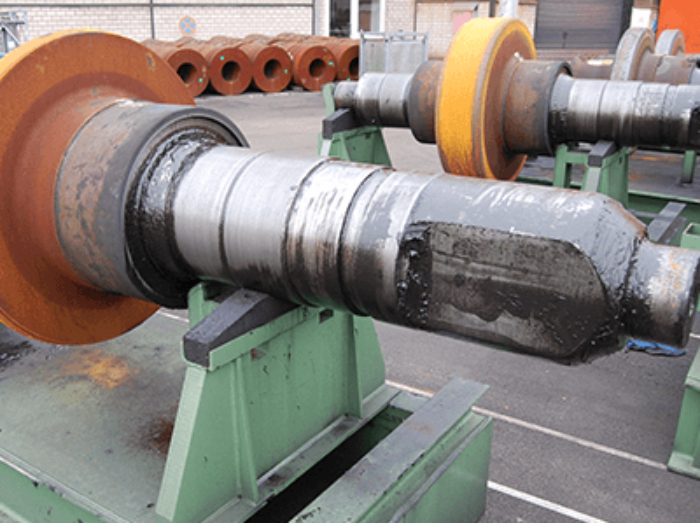

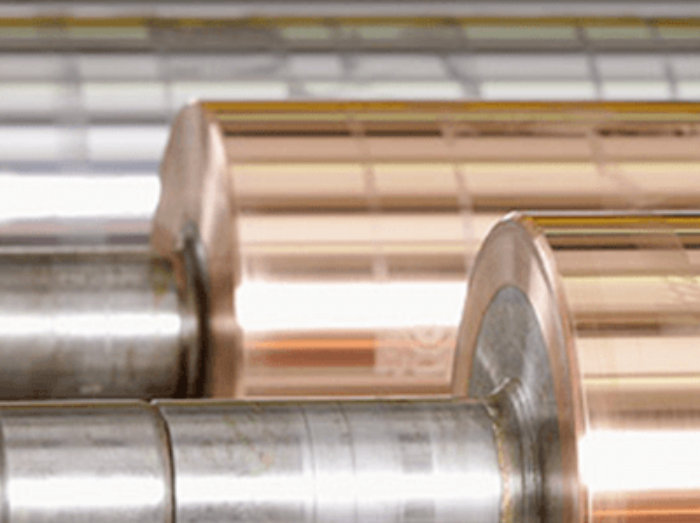

Preservation of high quality investment goods is always a big theme in steel and rolling mills. The induction heating technology is predestinated for the dismounting operation of shrink fits from rollers and shafts. Thanks to the innovative induction equipment tools from LEIFERT INDUCTION the period of inactivity and the maintenance intervals will be reduced.

LEIFERT INDUCTION supplies leading manufacturer of print rollers. The radial run out of the print rollers

will be defined by the manufacturing process of the blanks. As a basis for controlled and repeatable

manufacturing process the induction heating fulfill all requirements.

The induction heating process has decisive benefits towards classical heating methods like operating with

blow torches. The direct induction heating process into the roller is much more efficient and repeatable

than operating with an open gas flame.

The inductive heating treatment of rollers and cylinders is very homogenous and therefore the best

preparation for assembling the journal pins and rodents.

The innovative induction heating technology from LEIFERT INDUCTION is part of application for

manufacturing

of print rollers, cooling rollers and transport rollers.

PRODUCTS