The company LEIFERT INDUCTION provides first class products for mounting and dismounting of inner bearing

rings and labyrinth rings.

Due to maintenance reasons for wheel sets of railway shafts it is absolutely necessary to consider the

validated guidelines. To fulfill the requirements of maintenance the only chance is to work with

professional tools.

It is a big challenge to dismount shrink fits in the area of wheel set maintenance, because of very

tightened connections between ring and shaft. Towards mechanical dismounting methods which often damages

the bearing rings the middle frequency technology has a lot of benefits.

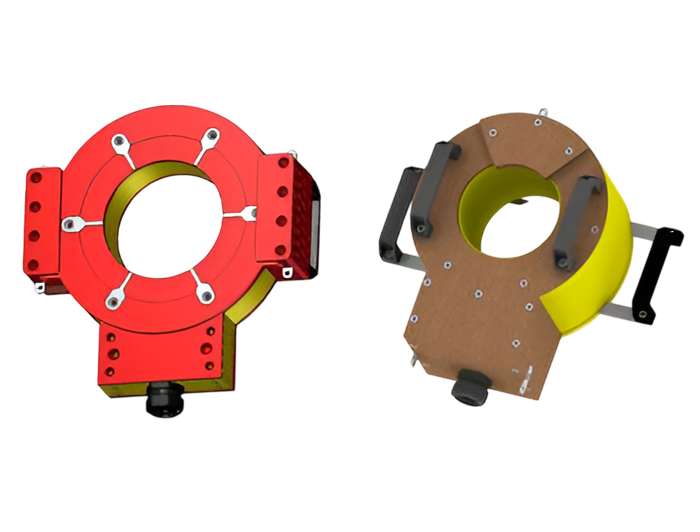

With especially developed induction equipment from LEIFERT INDUCTION the operator gets individual tools

of inner bearing ring induction coils and labyrinth ring induction coils.

The construction of the induction coils are very close to the customer to get an optimized and much

efficient tooling.

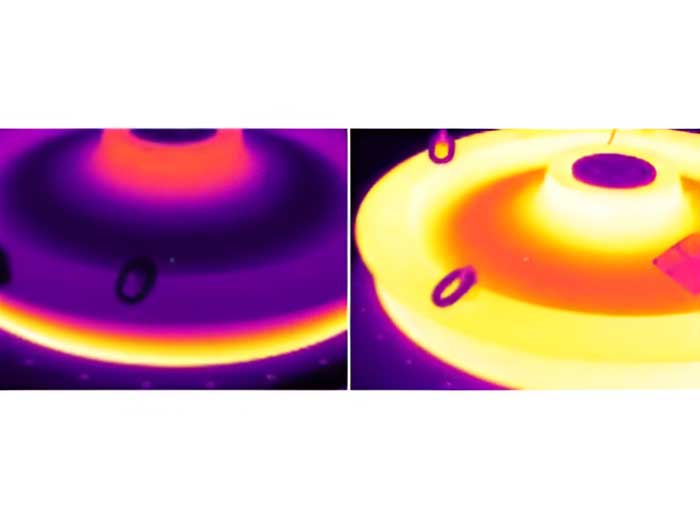

The induction coil transfers very high energy densities into the work pieces. Already well before the

shaft will extend the inner bearing ring and the labyrinth ring obtain sufficient temperature to remove

very easily.

Very sophisticated pull down appliances which are integrated in the induction coil make it very easy to

operate. The average time for dismounting takes approximately 30 – 40 sec.

The induction coil covers the inner bearing rings and after a heating time of approx. 25 sec. the inner rings obtain a temperature of approx. 140°C. For a short period of time it is now possible to dismount the inner bearing rings. Both inner bearing rings can be displaced from the shaft with the induction coil.

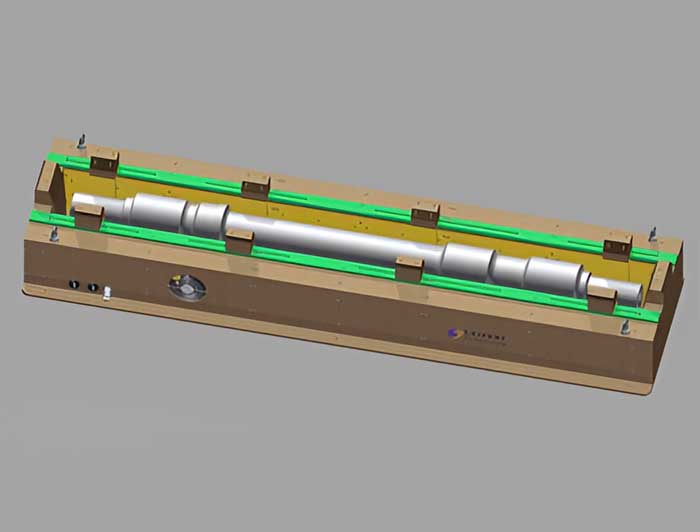

Before assembling all necessary parts on a wheel set shaft like bearings, labyrinth rings, wheels,

brakes and so on the seat fits needs to be coated with molybdenum. To prepare the wheel set shaft for

this coating it needs to be heated.

LEIFERT INDUCTION develops special induction coils for this preparing heating process. In the first

instance these kinds of induction coils were used for wheel set companies and maintenance companies for

rail vehicles.

The maintenance of steel tires is always a big challenge. LEIFERT INDUCTION provides special designed induction coils for mounting and dismounting of steel tires. For highly recurrent applications it is useful to operate with fixed coils. For often changing diameters it could be more efficient to work with flexible coils.

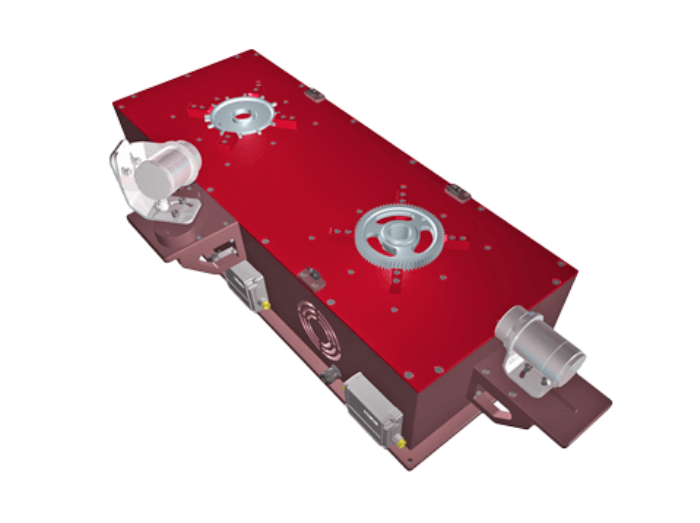

The requirements of extremely short cycle times in the area of automotive production is calling for modern

technology. The innovative induction equipment from LEIFERT INDUCTION is able to put the

heat well directed into complex shaped work pieces, so that assembly processes will be accelerated.

Pre heating table including contact free temperature measuring for single parts. Inductive heating of

camshaft sprocket and impulse whee

PRODUCTS