Lubrication Equipment

Grease Meter AM-GM-700

Features

The unit is used to show the exact quantity of grease that is fed into any specific application. The unit can be mounted on a manual pump or a grease gun.

A simple push on the button will set the meter at zero and the metering can be started. The result is measured in cm3 / gms / oz. / FI.oz. and is displayed in large digits.

Advantages

- Increases life of Bearings

- Exact measured quantity of grease is dispensed

- Easy to read and operate

- Making greasing efficient

- Resettable LCD display & backlight

- Industrial strength design

- Can be calibrated in house for different types of greases

-

Technical Data

Material, housing Aluminium, anodized Seals NBR Working pressure Max 70 MPa/10,000 psi Flow Max 1,000 cm³/min Measuring accuracy ±3% upp till 30 MPa (4 400 psi) Height of digits 9 mm Number of digits 4 Battery 1 piece of AA (1,5 V) Medium Grease up to NLGI 2 Weight 0.3 kg Connections ISO-R1/8 female

Lube Right

‘LubeRight’ is a computerized manual lubrication system with integrated hardware and software. Compared to traditional manual lubrication it offeres the following advantages:

- Each lubrication point is identified and the recommended amount of grease is clearly displayed. An accurate lubrication improves the life of the lubricated components.

- All lubrication points are confirmed and the system prevents that lubrication points are forgotten.

- Each lubrication point can be monitored by historical data.

- The actual performed lubrications are automatically recorded.

Each lubrication point is equipped with a passive transponder. The transponder has a unique identification number, and makes it possible to identify each lubrication point. The amount of grease that is to be discharged in the lubrication point is stored in memory and displayed on the display.

The grease meter records and stores the actual amount of lubrication. After the lubrication round, the data is transferred to a PC. The computer program shows how much grease was discharged into each lubrication point and also any deviations form the specified values. The system clearly warns if, for example, a lubricating point has been forgotten.

Lube Mon

‘Over the years engineers have repeatedly questioned the false security offered by a fully automatic centralized lubrication system and have preferred the old method of manual lubrication with its inherent problems. They claim that there is no guarantee that lubricant is reaching the bearing. Keeping this in mind Assalub developed, the first monitoring system that guarantees lubricant is discharged into the bearing with the correct amount each and every time.

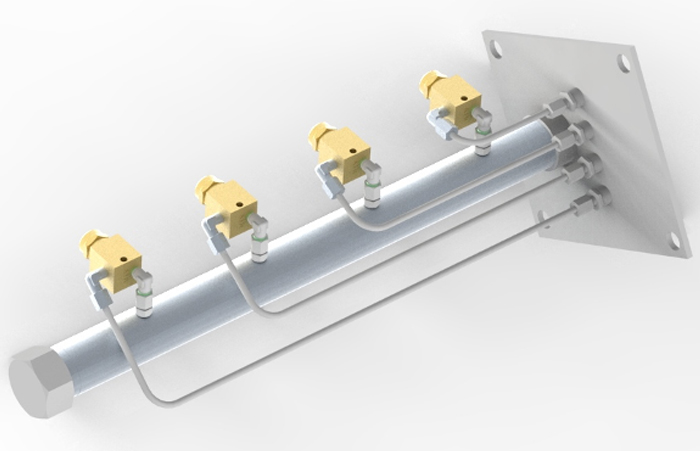

Measuring unit

The measuring unit is an accurate oval gear mechanism with a magnet integrated into one of the gearwheels.

The body of the unit incorporates a reed switch element which senses the magnet passing. Each single revolution of the oval gears has a displacement of 0.655 cm3.

LubeMon is available in two versions Anodized Alluminium and Acid-Proof Steel.

Monitoring can be done with two different alternatives. One control unit for maximum 10 greasing points and one PC based data base system for practically controls number of points.

-

Technical Data

Flow : 0 - 2500 cm3 / min Accuracy : Grease NLGI 2: 0.655

cm3 / pulse ± 3%

Oil ISO-VG 150:

0.610cm3 / pulse ± 3%Max. Pressure : 70 MPa / 10150 psi Vibrations : 20 G (10-20 000 Hz) Life Time : 109 pulses (655 m3)

at l < 10 mATemperature : -20oc - +70oc Connection : ISO-G1 / 8 Dimensions excl connector : LxWXH : 55 × 40 × 38mm Electrical data : Protection : IP 67 Connection : 4-pol std. M12 1 male,

signal pin 1 and 4Voltage : 0 - 24 V DC Current : max. 0.20 A

Zero Residual Pump

Features

Losing expensive grease, because a grease drum can not be completely emptied is one of the major problems affecting the working on the shop floor. To overcome this perpetual problem, a new unique pump is now available.

These pumps are drum mounted and fitted on top of the follower plate and descend with it as the grease level falls in the drum. With this arrangement a drum can be emptied almost completely.

Advantages

- Saves grease and money

- A kg. or less of a grease is wasted

- Easy to see grease level in drum at a distance

- No destruction costs

- Reliable operation

Open Grease Spray System

Features

Lubricating large open gears is not easy that too in harsh operating conditions & the large area to cover. Hence Assalub offers a tailored made solution for optimum lubrication of open gears utilising their Open Gear Grease Spray system.

Lubrication is essential to ensure trouble-free operation of these gear drives and extend their mechanical lifetime.

The typical area for this Open Grease Spray system is Cement industry, Mining Industry, Steel & Fertilizer plants. They are used on various types of machines converting large quantities of materials: tubular mills, cooling, washing and drying drums, rotary ovens and incinerators..

Advantages

- Few components

- High quality components

- Easy to install

- Gives a safe and reliable system

PRODUCTS

- Bearing Housings / Plummer Blocks & Adapter / Withdrawal Sleeves

- TM Induction Heater

- Leifert Induction Heaters

- JUNG Hydraulic Toe Jacks / Transport Trolleys / Industrial Skates

- Edmolift Scissor Lifts and positioners

- Renova Movicart and Tuggers

- Aerofilm Air Caster

- Fada Heavy Material Movement Trolleys

- 3 ARM Work Positioner and Manipulator

- Omar Star Hydraulic & Mechanical Pullers / Pushers

- Deep Groove Ball Bearing Puller

- Fastener Extractor

- Pipe Repair Clamps / Couplings

- S-Force Hydraulic Jacks & Pumps

- Lubrication Equipment

- Wedge lock Washers & Nuts

- Bearing Fitting Tool Kit Model AM 100 Mark III & IV

- Industrial Stethoscope Model AM 200 Mark I

- Bearing Monitoring Tool Model AM 800

- Tachometers & Thermometers

- Vibration Meters

- Belt / Sheave Laser Alignment Tool

- AI based Wireless Vibration Monitoring