Different kinds of work pieces for manufacturing of windmills need to be heated.

The advanced air cooled middle frequency induction systems from LEIFERT INDUCTION have set a standard in the

European wind branch.

Beside many other benefits this innovative technology from LEIFERT INDUCTION guaranteed repeatability, time

savings, eco-friendliness, low noise emissions and user friendly operation.

Additionally the compact design and the air cooled construction are qualified for mobile operation.

In several cases it is not only a big advantage to heat up the workpieces before assembling but it is very necessary to use induction heating. Due to big benefits like repeatability, eco-friendliness, time savings, low noise emissions and easy operating the induction heating was generally accepted in the wind mill branch. The compact design and the air cooled construction are qualified for mobile operating during the process of manufacturing so that single tasks and serial tasks can be well done.

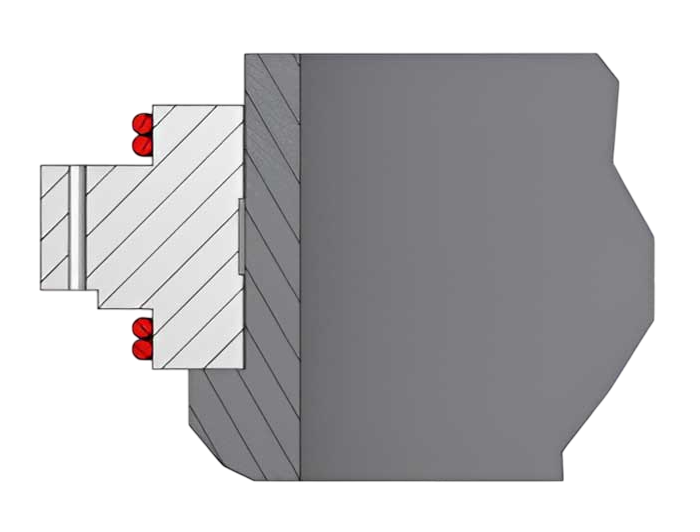

Due to close tolerances the demands on large bearings and main bearings are growing up. Every task for mounting and dismounting can be solved with individual designed induction heating equipment from LEIFERT INDUCTION.

The dismounting of main bearings requires a lot of attention. LEIFERT INDUCTION has numerous experiences in this area and supports many kinds of such projects.

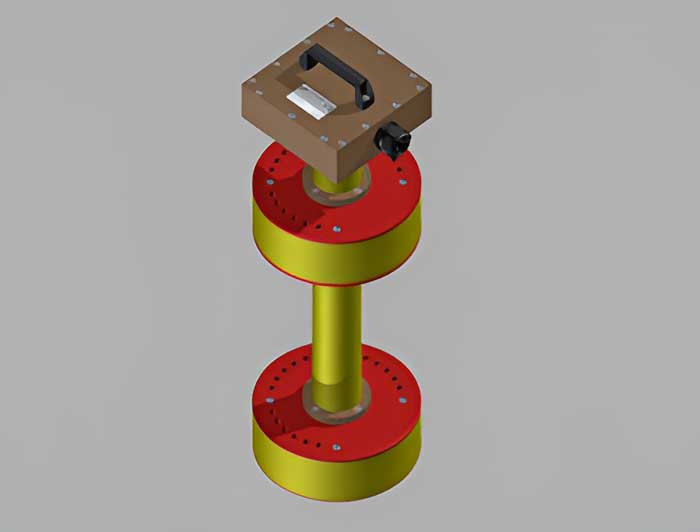

Very often it is necessary to heat up main frames of wind mills. Large masses need to be heated up within short times. The induction heating equipment from LEIFERT INDUCTION ensures short set-up and process times.

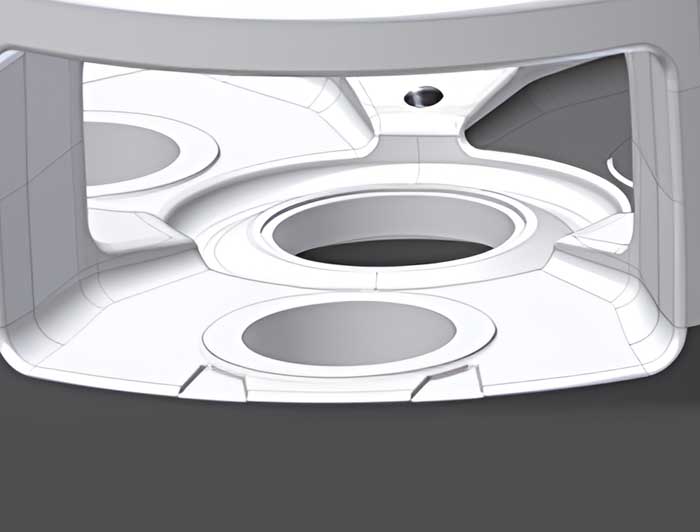

A special developed fixed induction coil will be used for mounting of rotor hubs. Placed within very short time the induction coil is ready to use. Due to intelligent design incorrect operation is not possible. Process reliability and repeatability of the process are guaranteed.

By reason of uneven distribution of mass planet gears pose a challenge for inductive heating equipments. For mounting of the pins two bearing seats have to be heated up at the same time.

In long term experiences with gear manufacturers LEIFERT INDUCTION develops special induction coils. For every planet gear these kinds of induction coils were developed and produced.

LEIFERT INDUCTION provides inductive heating systems to famous producers and maintenance

companies in the

area of aircraft technology. For the aircraft industry it is very important to ensure high quality in the

process of production with controlled and exactly repeatable processes. Due to this reason inductive

heating systems will be implemented at aircraft and maintenance companies more often.

The innovative and flexible air cooled induction systems from LEIFERT INDUCTION meets the

requirements of

the aircraft industry with the benefits of high economic efficiency in the area of production.

PRODUCTS