There are many factors involved when considering the right movement solution. For example, how flexible

do you want to be with the tooling? How often do you need to move it? What (weight) variation is there

and what needs to be moved? You can also add additional features, making it even more user-friendly for

the operator.

For weights up to approximately 10.000 kg it is not necessary to use a drive. Because there is almost no

friction, you can move 1.000 kg with 1 kg of force. But make sure to have several people around as you

do it, as they remain large weights.

With our modular Air caster system, you have a cheap and flexible solution for moving weights. You can

easily store these after use, take them everywhere and use them in different applications. There are

different systems, each of which can move a wide range of weight. A big advantage is that you only need

one inch of free clearance to place the casters. If the height of the transport is critical, this is the

lowest solution on the market.

Would you like to know more about our solutions from 500 kg to 10.000 kg, or personal

advice?

Contact us for more information.

When moving heavy weights, you can opt for a flexible solution, such as a modular Air caster system.

These standard solutions are ideal for weights up to 100.000 kg. Especially if you want to move multiple

different sizes or awkwardly shaped objects. This solution is safe, inexpensive and widely applicable.

Is relocation a daily part of your production process? Do you have to carry out regular maintenance on

your machinery? In such cases, you can opt for a transporter that is ready to use even faster and is

further adapted to your wishes and situation. This can be a standard solution or a customized

transporter. This allows you to work even more effectively and ensure that your output is further

optimized.

Would you like to know more about our solutions from 10.000 kg to 100.000 kg, or a personal

advice?

Contact us for more information.

This reliable method is used in various industries every day. Transformers are built on a pallet that

moves on Air casters through the factory into the test room. But ship propellers are also accurately

positioned during installation. Complete aircrafts are moved through the warehouse during maintenance.

What about turntables with subsea cables that weigh up to 10 million pounds? If you have a question

about moving extremely heavy weights, please contact us here to discuss the possibilities.

Our engineers have years of experience optimizing production environments, especially when it comes to

intralogistics issues. In doing so, we work closely with partners that have broad experience in

automation. This way we bring the best of both worlds together: our experience and knowledge of Air

casters combined with experience optimizing production environments and automation.

Would you like to know more about our solutions of 200,000 lbs or more, or personal advice?

Contact us for more information.

Air casters ensure a safe and controlled way of moving even with weights up to 10.000.000 kg. In motion,

your ship or ship component can be moved and positioned very accurately. If desired, you can rotate your

ship on the spot which is impossible with other techniques such as cranes, wheels or rails. When moving

these weights, the load-bearing capacity of the floor is an important component. Where with wheels or

rails an enormous point- or line load is created, with Air casters the weight is evenly distributed over

the surface of the casters. The casters have a maximum working pressure of 4 bar, so the floor is never

loaded higher than 4 kg per square inch. When moving large weights in shipbuilding, it can be

interesting to consider Aqua Casters. This reduces the required volume to 5% compared to air. This can

have a significant energy advantage as well as significantly reduce operational costs.

Would you like to know more about shipbuilding, or would you like personal advice?

Contact us for more information.

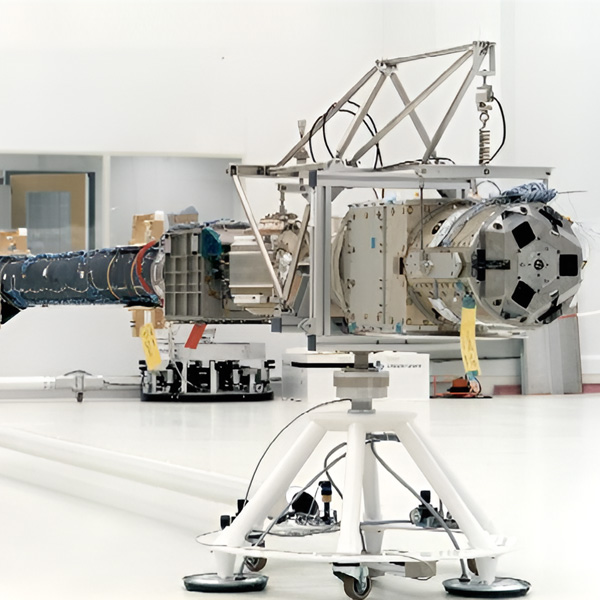

Air casters have been used in cleanrooms and the most critical environments since their inception due to

their excellent hygienic properties. The air used for their operation is very well controlled with

filters. The floor is often already good for using air skates and the special Polyurethane casters are

wear-free. This combination of factors ensures that there is virtually no risk of contamination. In

addition, there are no moving parts, therefore grease or other lubricants are not needed, reducing the

number of parts (that can possibly wear out). Air casters can also move machines vibration-free. This

provides even more benefits, including no re-calibration of sensitive machines or parts and very

accurate moving of modules, parts or complete machines. Air consumption of these cleanroom-suitable

casters is lower than that of the other types of Air casters. In addition, the design is made in such a

way that the vortices are directed to the ground and reduced to the absolute minimum. People walking

around create more air turbulence than the Air casters. This way we ensure that you can move any object

in critical environments risk free, in all cases.

Would you like to know more about our semiconductor solutions, or personal advice?

Contact us for more information.

Would you like to know more about Transformers production, or personal advice?

Contact us for more information.

A cleanroom is a controlled environment where pollutants like dust, airborne microbes and aerosol

particles are filtered out to provide the cleanest space possible. Most cleanrooms are used for

manufacturing products like electronics, pharmaceutical products and medical equipment. Depending on the

cleanroom class, a maximum number of particles is allowed per cubic foot. The aim is always to keep this

as low as possible. Measures are also taken to prevent the particles already present in the cleanroom

from floating around. With Air casters, this is not a concern. Our portfolio includes a special range of

Air casters that are wear-free, which reduces the risk of contamination to a minimum. The air used is

highly controlled and send out less movement than the people moving in the cleanroom. Air casters also

have no moving parts (thus no wear) and don’t require lubricants.

Would you like to know more about clean room and food industry solutions, or personal advice?

Contact us for more information.

Do you want to move a grandstand in the future? In that case you may be confronted with hard-to-reach

places. Air planks are particularly suitable for that. Do you have small cracks in the floor or

expansion joints that you must cross? Then the Gap Crossers offer the solution, which can also be

combined with these air planks or beams.

Are you developing a new stadium or seating modules? Contact us to learn more about our portfolio. In

case of frequent transfers, you mount casters permanently under your stage or seating stands. We work

closely with highly qualified partners who focus solely on the entertainment industry. Together we can

provide you with the best solution.

Would you like to know more about solutions within the entertainment industry, or personal

advice?

Contact us for more information.

The floor must be airtight and smooth. In many cases the floor (such as polished concrete floors)

already meets this requirement. If not, a solid rubber mat, thin steel or plastic sheets, the floor can

be added temporarily to prep for Air casters, making it easy to get started in almost any location.

Air casters ensure that the floor is no longer damaged. The floor pressure is kept to a minimum and with

a single set you can handle a huge number of different situations. Partly for industrial movers, we have

put together the Aerofilm portable Air caster system. This portable rigging kit offers a solution for

the most common weight range (between 4.500 kg and 36.000 kg), is quickly operational and can easily be

taken anywhere in the transport box, while also requiring minimal investment.

Would you like to know more about industrial relocation or personal advice?

Contact us for more information.

In cable production, reels are often moved with product. When moving reels, where the diameters can rise

to more than 4.000 mm, it can become challenging to navigate doorways or other narrow spaces. With Air

casters you are assured of the lowest possible construction height. You can move omnidirectionally,

making tricky routes a lot easier. Various options are also possible, such as a level control system and

an integrated air hose reel.

Would you like to know more about cable production, or personal advice?

Contact us for more information.

Every organization has customers who often want something slightly different from the standard product

that is on the shelves. It depends on how you have set up your organization, whether you can or want to

meet this demand. Flexibility is becoming increasingly important in both consumer and business driven

organizations. Both companies and individuals want to distinguish themselves and have a separate

question about this. Sometimes it is possible, sometimes more difficult. We regularly see that it is

relatively easy to remove the standard product from a “conveyor belt” environment with Air casters, then

turn it into a “special” and place it back in the production environment. It takes some extra work, but

specials also come with a premium price and ditto margin. If you want to know whether there are

possibilities in your production environment, you can have a no-obligation sparring with one of our

engineers or application specialists.

Would you like to know more about our solutions for your production environment, or personal

advice?

Contact us for more information.

Aerofilm Systems has decades of experience moving various roll and reel products, with both standard and

custom made solutions, regardless of whether the roll is 500 kg or 3.000.000 kg .

If you would like to discuss your challenge within your industry, please contact one of our application

specialists here. There is more possible than you think. For example, we can pick up a reel that is

horizontal or vertically placed and turn it around, or even wind/unwinding it during the process.

Especially when positioning your product, you will experience a huge advantage with Air casters.

Discover the power of air.

Would you like to know more about moving rolls and reels, or personal advice?

Contact us for more information.

PRODUCTS